Cheaper LEDs from breakthrough in ZnO nanowire research

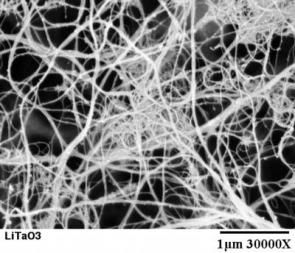

SEM image of p-type ZnO nanowires created by electrical engineering professor Deli Wang at UC San Diego . Note: the blue color was added in photoshop. Credit: Deli Wang/UCSD

Engineers at UC San Diego have synthesized a long-sought semiconducting material that may pave the way for an inexpensive new kind of light emitting diode (LED) that could compete with today's widely used gallium nitride LEDs, according to a new paper in the journal Nano Letters.

To build an LED, you need both positively and negatively charged semiconducting materials; and the engineers synthesized zinc oxide (ZnO) nanoscale cylinders that transport positive charges or "holes" – so-called "p-type ZnO nanowires." They are endowed with a supply of positive charge carrying holes that, for years, have been the missing ingredients that prevented engineers from building LEDs from ZnO nanowires. In contrast, making "n-type" ZnO nanowires that carrier negative charges (electrons) has not been a problem. In an LED, when an electron meets a hole, it falls into a lower energy level and releases energy in the form of a photon of light.

Deli Wang, an electrical and computer engineering professor from UCSD's Jacobs School of Engineering, and colleagues at UCSD and Peking University, report synthesis of high quality p-type zinc oxide nanowires in a paper published online by the journal Nano Letters.

"Zinc oxide nanostructures are incredibly well studied because they are so easy to make. Now that we have p-type zinc oxide nanowires, the opportunities for LEDs and beyond are endless," said Wang.

Wang has filed a provisional patent for p-type ZnO nanowires and his lab at UCSD is currently working on a variety of nanoscale applications.

"Zinc oxide is a very good light emitter. Electrically driven zinc oxide single nanowire lasers could serve as high efficiency nanoscale light sources for optical data storage, imaging, and biological and chemical sensing," said Wang.

To make the p-type ZnO nanowires, the engineers doped ZnO crystals with phosphorus using a simple chemical vapor deposition technique that is less expensive than the metal organic chemical vapor deposition (MOCVD) technique often used to synthesize the building blocks of gallium nitride LEDs. Adding phosphorus atoms to the ZnO crystal structure leads to p-type semiconducting materials through the formation of a defect complex that increases the number of holes relative to the number of free electrons.

"Zinc oxide is wide band gap semiconductor and generating p-type doping impurities that provide free holes is very difficult – particularly in nanowires. Bin Xiang in my group worked day and night for more than a year to accomplish this goal," said Wang.

The starting materials and manufacturing costs for ZnO LEDs are far less expensive than those for gallium nitride LEDs. In the future, Wang expects to cut costs even further by making p-type and n-type ZnO nanowires from solution.

For years, researchers have been making electron-abundant n-type ZnO nanowire crystals from zinc and oxygen. Missing oxygen atoms within the regular ZnO crystal structure create relative overabundances of zinc atoms and give the semiconductors their n-type, conductive properties. The lack of accompanying p-type ZnO nanowires, however, has prevented development of a wide range of ZnO nanodevices.

While high quality p-type ZnO nanowires have not previously been reported, groups have demonstrated p-type conduction in ZnO thin films and made ZnO thin film LEDs. Using ZnO nanowires rather than thin films to make LEDs would be less expensive and could lead to more efficient LEDs, Wang explained.

Having both n- and p-type ZnO nanowires – complementary nanowires – could also be useful in a variety of applications including transistors, spintronics, UV detectors, nanogenerators, and microscopy. In spintronics applications, researchers could use p-type ZnO nanowires to make dilute magnetic semiconductors by doping ZnO with magnetic atoms, such as manganese and cobalt, Wang explained.

Transistors that rely on the semiconducting properties of ZnO are also now on the horizon. "P-type doping in nanowires would make complementary ZnO nanowire transistors possible," said Wang.